One of the most satisfying aspects of our work here at Lucy Wagtail is the saving of old lampshades from landfill!

We walk a path of sustainability and encourage this where we can. One of the ways that we can help with this is by recovering, upcycling and refurbishing lampshades that have seen better days!

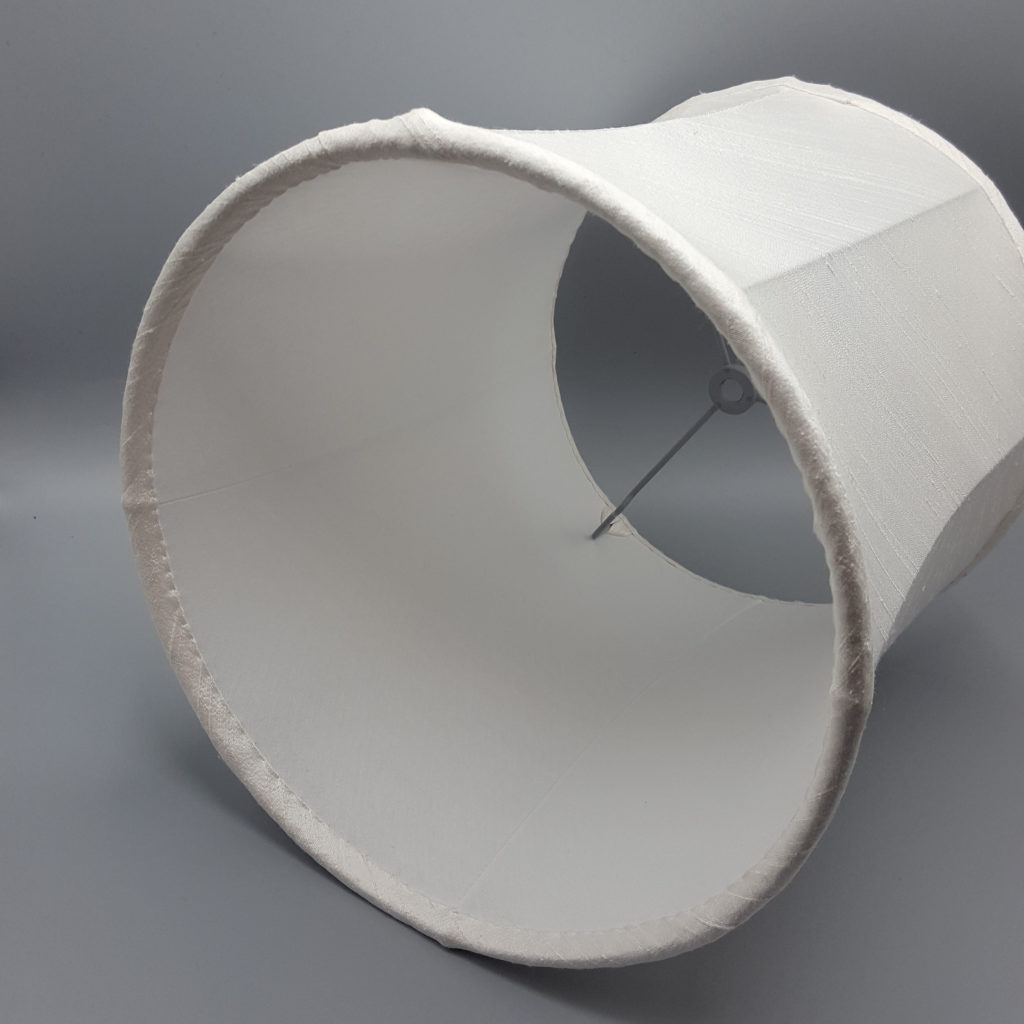

We’d like to take you on a journey of two particular lampshades which we refurbished recently from start to finish and hope you enjoy it and that it goes some way to showing the care and attention that goes in to breathing new life into a soft bodied lampshade. Follow the journey of our commission to create two refurbished ivory silk table lampshades with harp fittings.

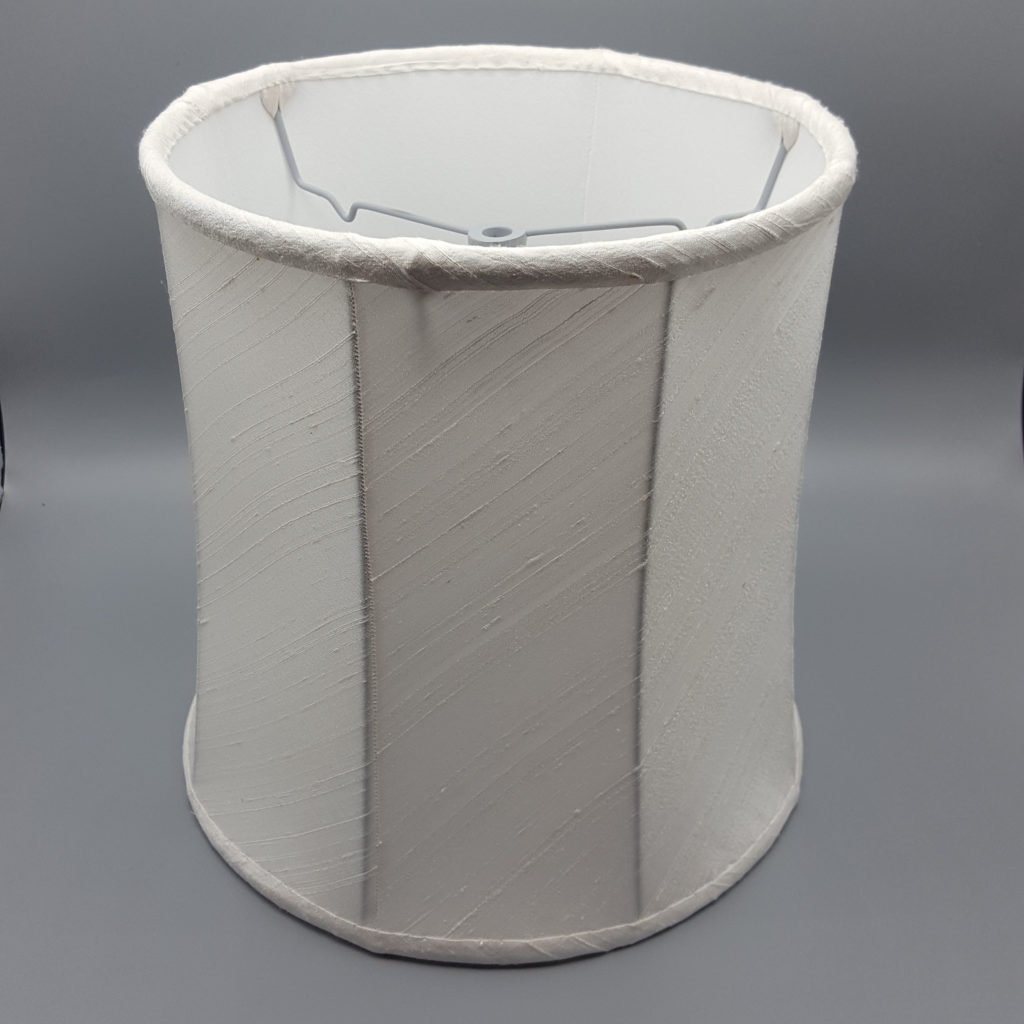

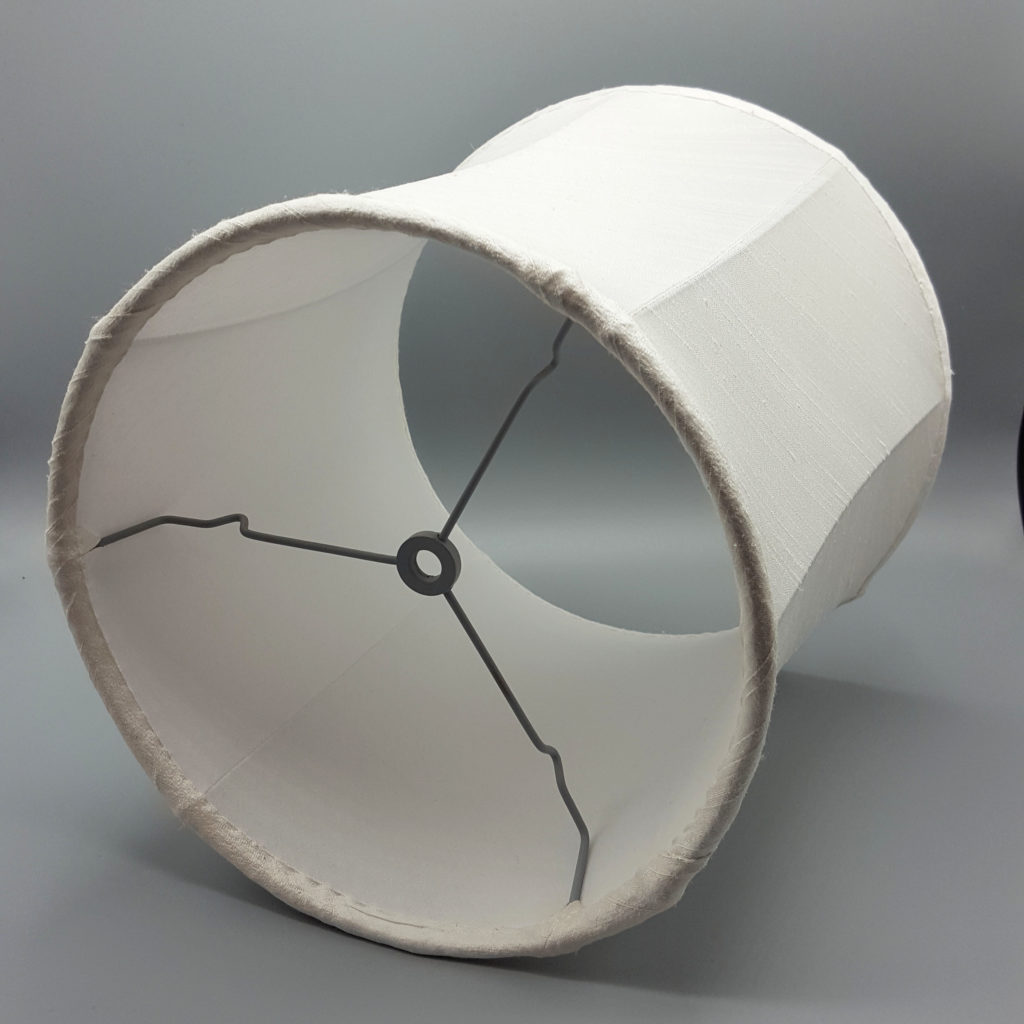

Our customer kindly took all these photographs before sending them to us so that we could assess the lampshades in readiness for the refurb. She then removed the old covering before posting the frames to us so that we could get down to giving these two gems a facelift!

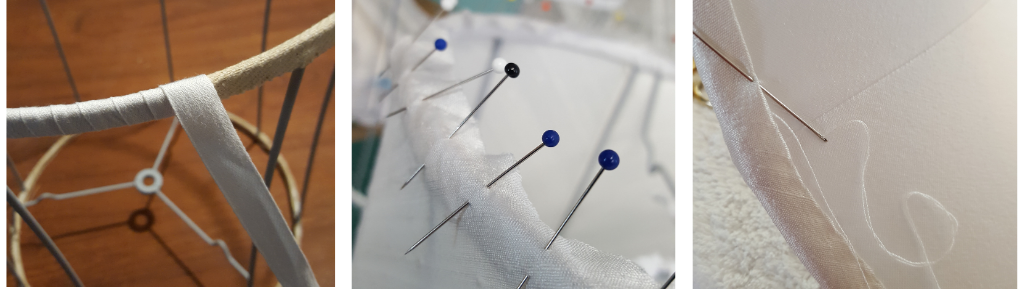

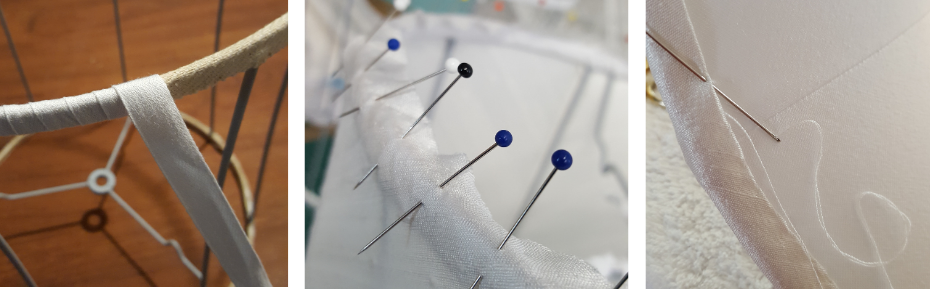

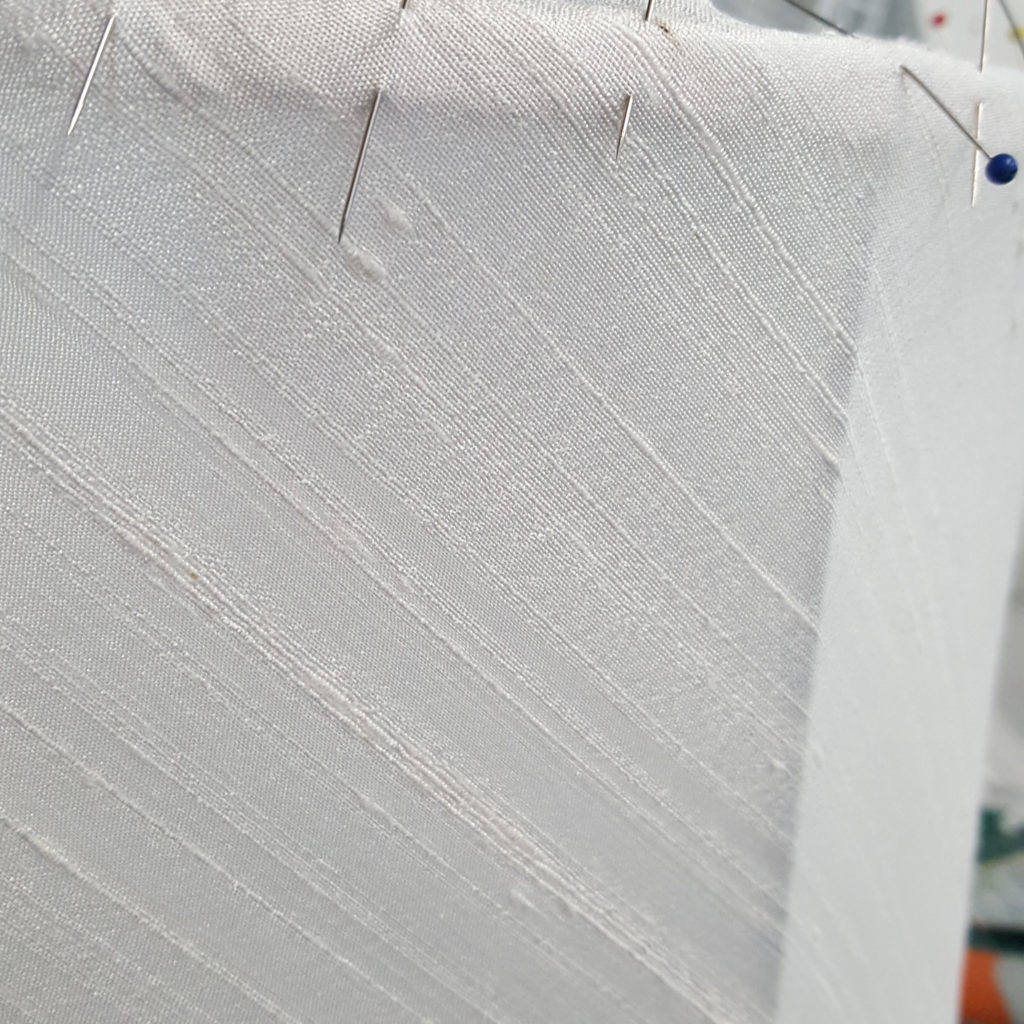

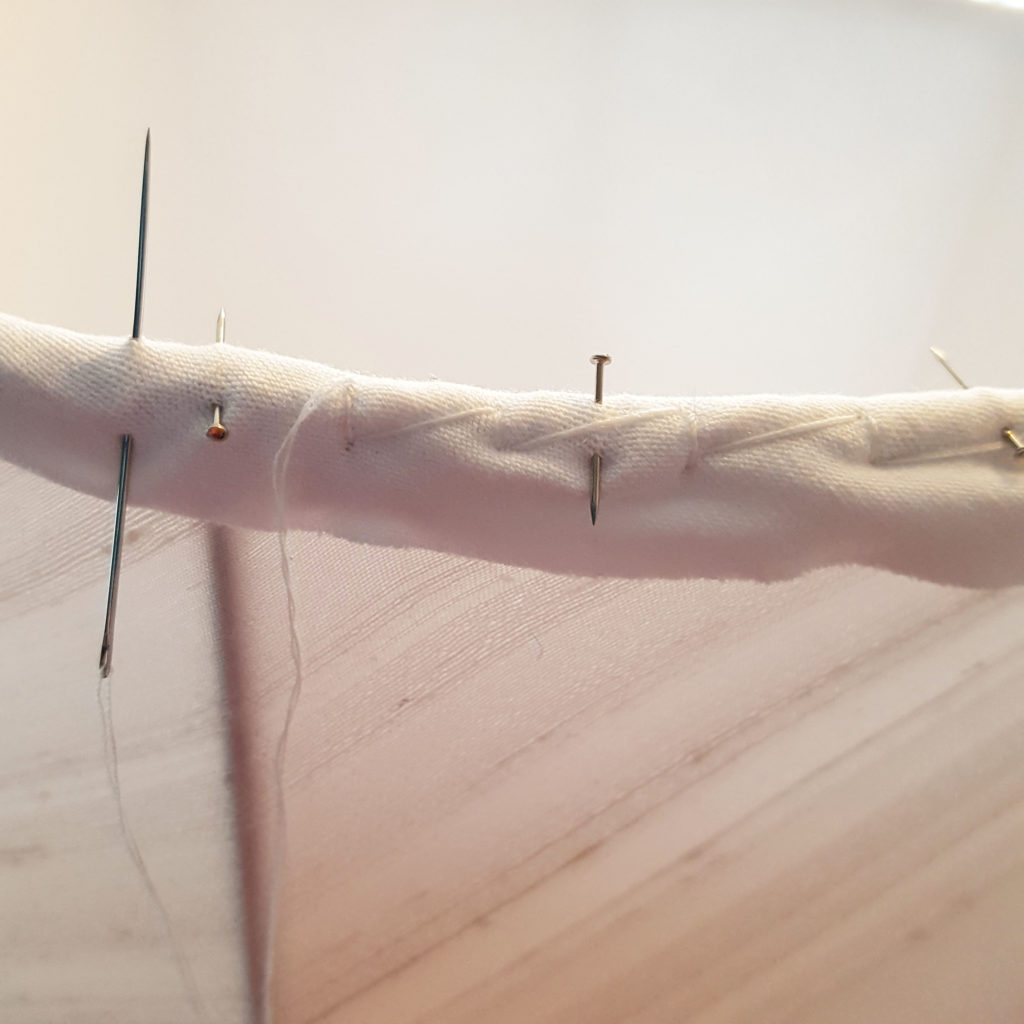

These types of refurbishments require a lot of hand sewing, in fact apart from using the sewing machine to stitch together the template pieces, everything else is hand sewn. We have to bind the frame top and bottom to create a base to stitch in to. Then of course create a template for the pieces that will become the lining and the exterior fabric of the lampshade. Both the exterior fabric and the lining must be cut on the bias to allow enough stretch to obtain a neat, taught finish.

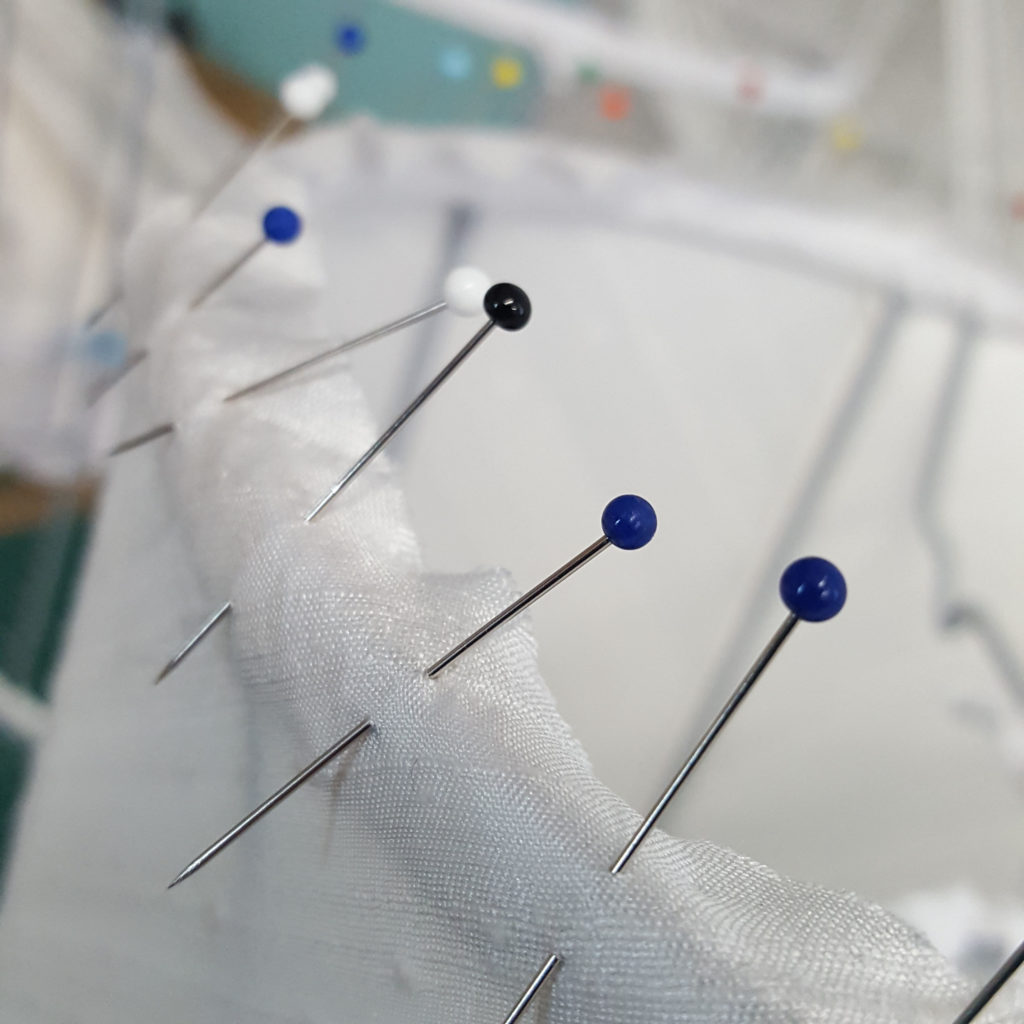

There’s a lot (and I mean A LOT!) of pins involved in hand stitching lampshades! For these lampshades we have used a gorgeous ivory dupion silk. These are used to ensure the fabric is taught enough to achieve the perfect fit before stitching in place.

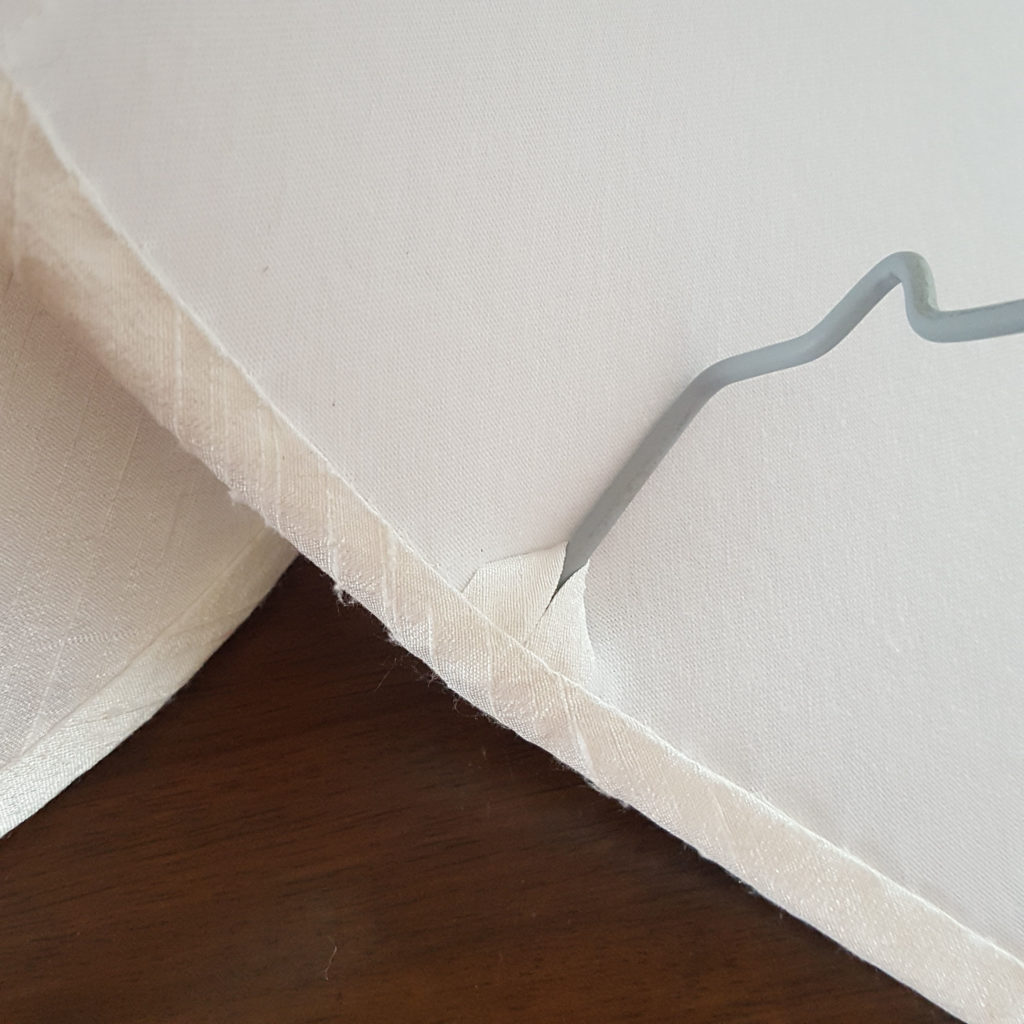

Once the exterior fabric has been hand stitched to the binding, the lining fabric is fitted, stitched on and trimmed before preparing the bias binding to finish the lampshades.

Super satisfying to be attaching the bias binding, finishing the lampshades off beautifully.